Locating pins, those unassuming yet indispensable components in engineering and machine design, play a crucial role in ensuring precision and accuracy across various industries. These diminutive fasteners, often overlooked by the untrained eye, serve as the unsung heroes in countless applications, from automotive assembly lines to intricate medical device fabrication. In this comprehensive exploration, we shall delve into the myriad scenarios where locating pins proves their worth, examining their diverse applications and the factors that influence their implementation.

The Fundamentals of Locating Pins

Before we embark on our journey through the diverse landscapes where locating pins finds their purpose, it is imperative to establish a solid foundation of understanding regarding these essential components.

How to Define Locating Pins?

Locating pins are small, often cylindrical machine elements designed to provide precise positioning and alignment in mechanical assemblies. These seemingly simple non-threaded fasteners play a pivotal role in maintaining consistency and accuracy in manufacturing processes, ensuring that components fit together seamlessly and function as intended.

Locating pins are often used to secure the position of two or more components of a machine relative to each other. While their appearance may be unassuming, locating pins boast a carefully engineered design that contributes to their effectiveness. Typically crafted from durable materials such as hardened steel or stainless steel, these pins often feature tight tolerances and smooth surfaces to facilitate their primary function of alignment and positioning.

Benefits of Using Locating Pins

Precision Alignment: Using locating pins guarantees parts are in the correct position.

Reduction of Errors: They can minimize the chances of misalignment.

Efficiency: These fasteners speed up the assembly process.

Durability: Locating pins are often made from robust materials for long-term use.

Factors to Consider When Using Locating Pins

Material Selection: The choice of material depends on the application’s requirements.

Size and Shape: The locating pins must match the aligned parts’ design specifications.

Load Capacity: The pin must withstand the forces it will be subjected to.

Environmental Conditions: The operating environment can affect the pin’s performance and life.

Where Should Locating Pins Be Used?

1. The Sector of Manufacturing

The manufacturing sector stands as one of the most prolific users of locating pins, with these components finding their way into countless applications across diverse industries.

1.1 Automotive Assembly: Precision in Motion

In the fast-paced world of automotive manufacturing, where precision and efficiency reign supreme, locating pins emerge as indispensable allies. These unassuming fasteners play a crucial role in ensuring that various parts of a vehicle, from body panels to engine components, align perfectly during assembly.

1.2 Aerospace: Where Millimeters Matter

The aerospace industry, with its stringent requirements for safety and performance, relies heavily on the precision afforded by locating pins. In the assembly of aircraft components, where even the slightest misalignment could have catastrophic consequences, these pins serve as guardians of accuracy. From the positioning of fuselage sections to the alignment of critical avionics systems, locating pins ensures that every element fits together with unerring precision.

2. The Realm of Precision Machinery

Beyond the realm of large-scale manufacturing, locating pins find their calling in the world of precision machinery, where accuracy is measured in microns rather than millimeters.

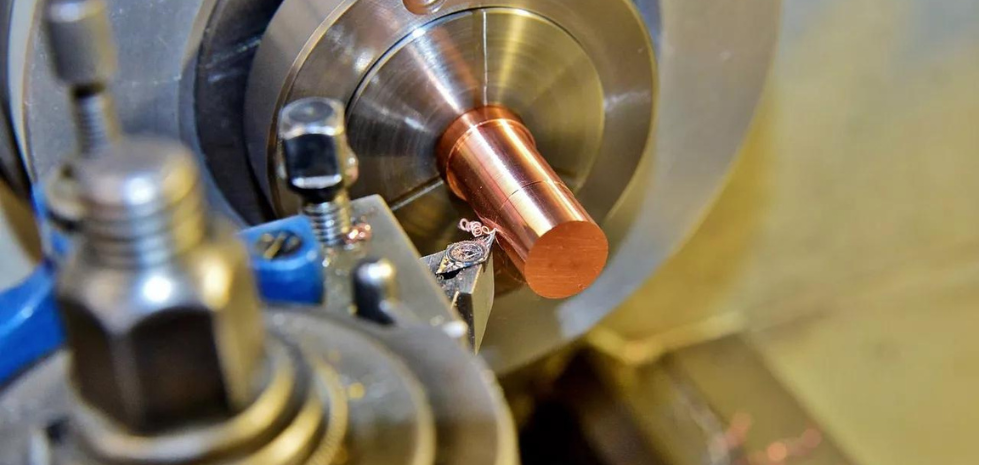

2.1 CNC Machining: Precision First

Computer Numerical Control (CNC) machining, a cornerstone of modern manufacturing, relies heavily on the precise positioning provided by locating pins. These components play a vital role in securing workpieces to machine tables, ensuring that each cut, drill, or mill operation is executed with high accuracy.

2.2 Injection Molding: Shaping the Future

In the realm of injection molding, where molten plastics are transformed into intricate components, locating pins serve as silent sentinels of quality. These pins are instrumental in aligning mold halves, ensuring that each part produced meets exacting specifications.

3. The Medical Frontier

The medical industry, with its unwavering commitment to patient safety and well-being, has embraced locating pins as essential tools in the pursuit of precision healthcare.

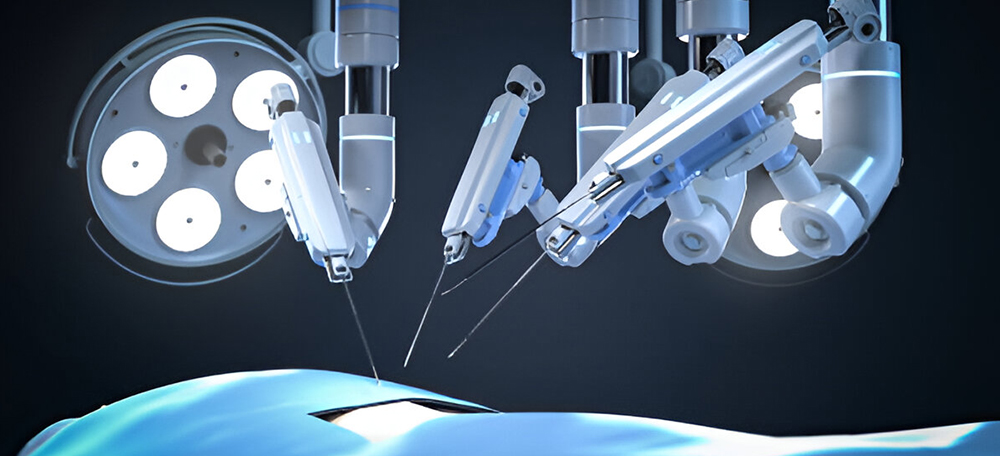

3.1 Surgical Instruments: Accuracy in the Operating Room

In the high-stakes environment of surgical procedures, where millimeters can mean the difference between success and failure, locating pins play a crucial role in ensuring the accuracy of surgical instruments. From the alignment of cutting guides in orthopedic procedures to the positioning of implants in dental surgery, these pins contribute to improved patient outcomes and reduced complications.

3.2 Medical Device Manufacturing: Engineering for Life

The production of medical devices, from pacemakers to prosthetics, demands an unparalleled level of precision. Locating pins find their purpose in this field by ensuring the accurate assembly of complex components, contributing to the reliability and effectiveness of life-saving devices. The consistency provided by these pins translates directly into improved patient care and enhanced quality of life.

4. The World of Consumer Electronics

As our society becomes increasingly reliant on electronic devices, the role of locating pins in ensuring their functionality and reliability cannot be overstated.

4.1 Smartphone Assembly: Precision in Your Pocket

The sleek smartphones that have become an integral part of our daily lives owe much of their reliability to the precision afforded by locating pins. These components play a crucial role in aligning various elements within the device, from the positioning of circuit boards to the placement of camera modules. The result is a seamlessly integrated device that functions flawlessly, despite its compact size.

4.2 Computer Hardware: Building the Digital Backbone

In the realm of computer hardware, where data processing occurs at lightning speeds, locating pins serve as the unsung heroes of precision. From the alignment of processor sockets on motherboards to the positioning of hard drive components, these pins ensure that each element of a computer system functions in perfect harmony.

5. The Field of Robotics and Automation

As we venture into an increasingly automated future, locating pins continues to play a vital role in ensuring the precision and reliability of robotic systems and automated production lines.

5.1 Industrial Robotics: Precision in Motion

In the realm of industrial robotics, where machines perform complex tasks with unerring accuracy, locating pins serve as crucial reference points. These components assist in the calibration and alignment of robotic arms and end effectors, ensuring that each movement is executed with the utmost precision.

5.2 Automated Assembly Lines: Consistency at Scale

Automated assembly lines, the backbone of modern mass production, rely heavily on the precision afforded by locating pins. These components ensure that each station in the assembly process maintains perfect alignment, facilitating the seamless transfer of workpieces from one stage to the next.

6. The Energy Industry

As the world grapples with the challenges of sustainable energy production, locating pins find a new purpose in ensuring the efficiency and reliability of power generation systems.

6.1 Wind Turbine Manufacturing: Harnessing Nature’s Power

In the production of wind turbines, where massive components must come together with exacting precision, locating pins play a crucial role. These components ensure the proper alignment of turbine blades, gearboxes, and generators, contributing to the overall efficiency and life of these renewable energy systems.

6.2 Nuclear Power Plants: Precision Under Pressure

In the high-stakes environment of nuclear power generation, where safety is paramount, locating pins serve as silent guardians of precision. These components are instrumental in the assembly and maintenance of reactor components, ensuring that critical systems align perfectly and function as intended. The result is improved safety, reliability, and efficiency in the production of nuclear energy.

Summary

Locating pins are a critical component in various industries, ensuring the precision and accuracy of assembly processes. By understanding their applications, types, and the factors to consider when using them, manufacturers can optimize their production lines and maintain high-quality standards. The use of locating pins is not just about alignment; it’s about ensuring the reliability and performance of the final product.

Are you looking for locating pins with high-quality locating pins? Don’t hesitate to visit FAR EAST TECH Overseas Product Mall (Website: https://www.fareasttech.com/ ).