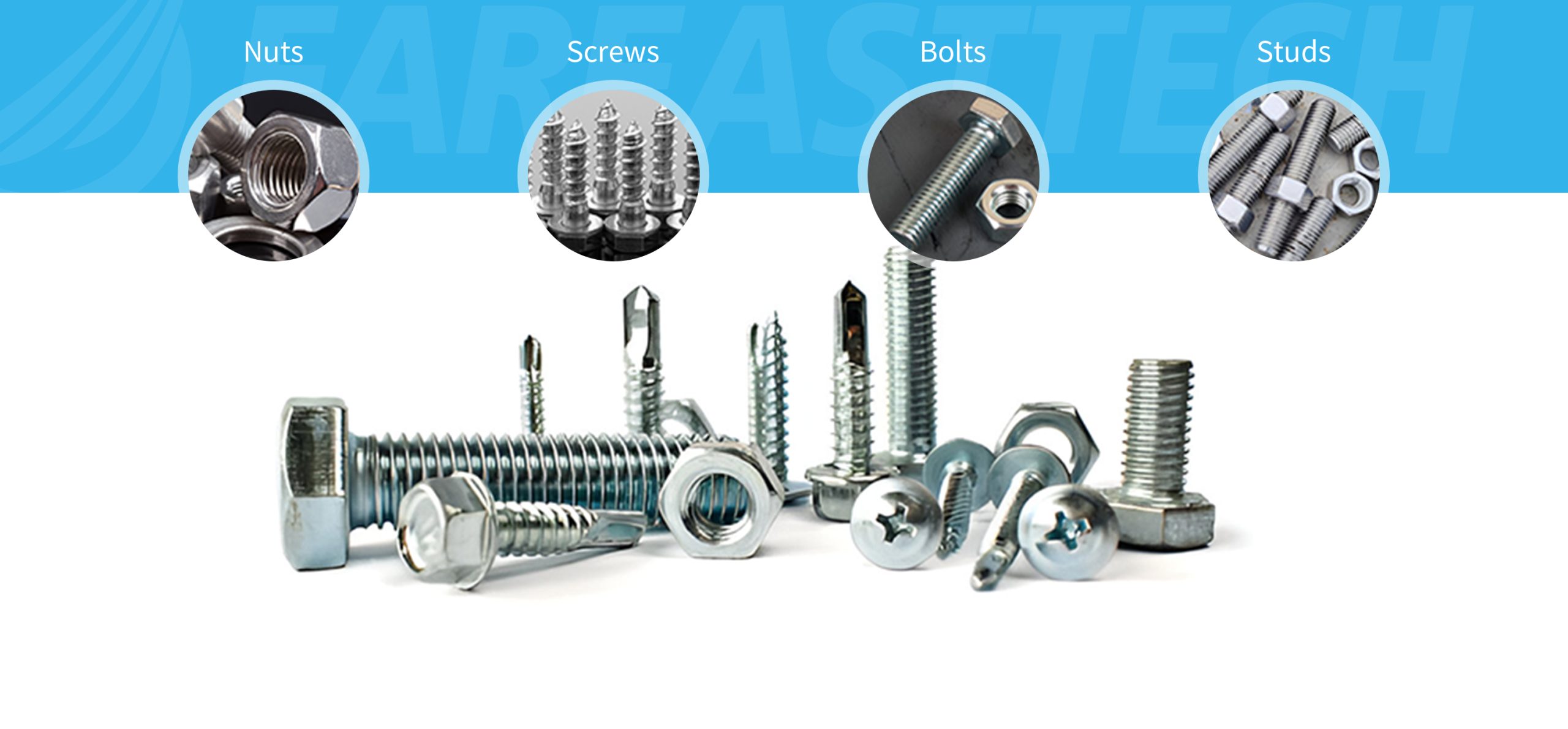

In construction, engineering, and DIY projects, fasteners are crucial in holding structures together. Among these essential components, nuts, screws, bolts, and studs stand out as the most commonly used and versatile options. While they are very closely related, each of these fasteners has unique differences. This article aims to demystify these differences, giving a further understanding of each type of fastener and its specific applications.

The Fundamentals of Fasteners

Before we get into the explanation of nuts, screws, bolts, and studs, it’s essential to understand the basic concept of fasteners. Fasteners are mechanical devices used to join two or more objects together, either permanently or temporarily. They come in various shapes, sizes, and materials, each designed to meet specific requirements in different applications.

What are Nuts?

Nuts are often overlooked, but they play a crucial role in many fastening systems. They are a type of fastener with a threaded hole. These small, typically hexagonal-shaped components feature an internal thread that allows them to be screwed onto bolts or other threaded fasteners. The primary function of a nut is to provide a strong, stable connection that can withstand significant force.

Common Types of Nuts

“Nuts” are essential metal fasteners with threaded holes. Here are some common types of nuts:

Hex Nuts: Hex nuts are the most common type, featuring six flat sides.

Wing Nuts: Wing nuts are equipped with “wings” for easy hand-tightening.

Lock Nuts: Lock nuts are designed to resist loosening due to vibration.

Acorn Nuts: Acorn nuts feature a domed top for a finished appearance.

Flange Nuts: Flange nuts have a wide flange at the base, which distributes the load over a larger area and can eliminate the need for a washer.

T-Nuts: T-nuts are designed to be embedded in wood or other soft materials, providing a threaded insert for bolts or machine screws.

Coupling Nuts: Longer than standard nuts, coupling nuts are used to join two threaded rods or bolts end-to-end.

Cage Nuts: Cage nuts are designed to clip into square holes in sheet metal, providing a threaded attachment point in thin materials.

Weld Nuts: These nuts are designed to be welded onto a surface, creating a permanent threaded attachment point.

Applications of Nuts

Nuts find applications in various industries, including:

Automotive: Securing engine components and wheel assemblies.

Construction: Joining structural elements and machinery.

Furniture: Assembling chairs, tables, and other pieces.

Electronics: Mounting circuit boards and components.

What are Screws?

Screws are fasteners with an external helical thread that can be tightened or loosened by applying twisting force to its head. They are designed to be driven into materials by turning, which causes the material to compress around the screw, creating a secure fit. Screws might be inserted into holes in assembled parts or a screw may form its thread. They come in a wide variety of shapes, sizes, and thread patterns, making them suitable for numerous applications.

Structure of a Screw

Head: The top portion which is designed for driving the screw.

Shank: The smooth part of the screw between the head and threads.

Thread: The helical ridge that gives the screw its gripping power.

Tip: The pointed end that initiates penetration into the material.

Common Types of Screws

Screws are essential fasteners used in various applications, from construction to electronics. Here are some common types of screws:

Wood Screws: Wood screws are designed for use in wood, these screws have a sharp point and coarse threads for better grip.

Machine Screws: Machine screws are used with nuts or in tapped holes, machine screws have a uniform thread along their entire length.

Self-Tapping Screws: They can create their threads in pre-drilled holes without the need for a separate tapping process.

Self-Drilling Screws: A combination of self-tapping and wood screws, these screws can both drill and tap their hole.

Socket Screws: These screws have a hexagonal or square socket in the head that requires a wrench or a screwdriver with a similar shape.

Pan Head Screws: A flat, round head with a single driving line, commonly used in furniture and general woodworking.

Button Head Screws: Similar to pan head screws but with a lower profile and a rounded top.

Flat Head Screws: These screws have a countersunk head that sits flush with the surface of the material.

Phillips Screws: A type of screw with a cross-shaped recess that requires a Phillips screwdriver.

Allen Screws/Hex Screws: Also known as hex screws, Allen Screws have a hexagonal socket in the head.

Lag Screws: Large, heavy-duty screws used to join heavy timber or structural steel.

Applications of Screw

Screws are ubiquitous in many industries and everyday objects:

Construction: Attaching drywall, flooring, and roofing materials.

Woodworking: Joining wood pieces in furniture and cabinetry.

Electronics: Securing components within devices.

Automotive: Fastening interior panels and accessories.

What are Bolts?

Bolts are externally threaded fasteners designed to be used with nuts or tapped holes. They fasten objects with unthreaded holes together, which is achieved by applying a twisting force to a matching nut. Bolts are typically stronger and larger than screws, making them ideal for heavy-duty applications.

Structure of a Bolt

Head: Usually hexagonal or square-shaped for easy tightening.

Shank: Can be partially or fully threaded.

Thread: Coarser than screws, providing greater strength.

Tip: Generally flat or slightly rounded.

Typical Types of Bolts

Bolts are a common type of fastener used in various applications to join materials together. Here are some typical types of bolts:

Hex Bolts: Also known as hex cap screws, these have a hexagonal head and are used in a wide range of applications due to their ease of use with wrenches.

Carriage Bolts: These bolts have a rounded domed head that sits flush against a surface, often used in wood and other materials that require a smooth appearance.

U-Bolts: U-shaped with threaded ends, they are used to secure pipes, rods, or other cylindrical objects.

J-Bolts: Similar to U-bolts but with a hook at the end, used for securing pipes or other objects to concrete or masonry.

Shoulder Bolts: Shoulder Bolts a specialized fasteners characterized by a wide smooth shank and a small threaded section at its tip. This design allows it to function as a pivot pin or attachment point.

Applications of Bolt

Bolts are essential in numerous industries and structures:

Construction: Joining steel beams and concrete elements.

Automotive: Securing engine mounts and suspension components.

Machinery: Assembling heavy equipment and industrial machinery.

Bridges: Connecting structural members in large-scale projects.

What are Studs?

Studs are threaded rods without heads, designed to be used in tension. They are relatively long rods that are threaded on both ends. Studs offer unique advantages in certain applications where traditional bolts or screws may not be suitable.

Stud Characteristics

- Fully threaded or partially threaded along their length.

- No head, allowing for flush mounting.

- Often used in pairs or groups for increased strength.

- Can be welded or press-fit into one component.

Types of Studs

Studs are a type of fastener that is used in various applications to secure parts together. Here are common types of studs:

Fully Threaded Stud Bolts: These are studs that have threads along their entire length. They are used in applications where a long thread engagement is required, such as in heavy machinery or in structural connections.

Tap-End Stud Bolts: These studs have threads at extreme ends of the body with unequal thread engagement length.

Double-End Stud Bolts: Also known as double-ended studs, these have equal threads on both ends.

Applications of Stud

Studs can find use in various specialized applications:

Automotive: Exhaust system mounting and engine assembly.

Marine: Securing deck fittings and equipment on boats.

Industrial: Mounting heavy machinery and equipment.

Aerospace: Attaching components in aircraft structures.

Summary

Through the above introduction, we have roughly understood the difference between nuts, screws, bolts, and studs. Each type of fastener has unique properties and applications, making them indispensable in various industries. Choosing the right one can make a more secure connection, and ensure the reliability of their projects. FAR EAST TECH has various fasteners with high quality and precision. If you are interested, please visit our overseas product mall (Website: https://www.fareasttech.com/).