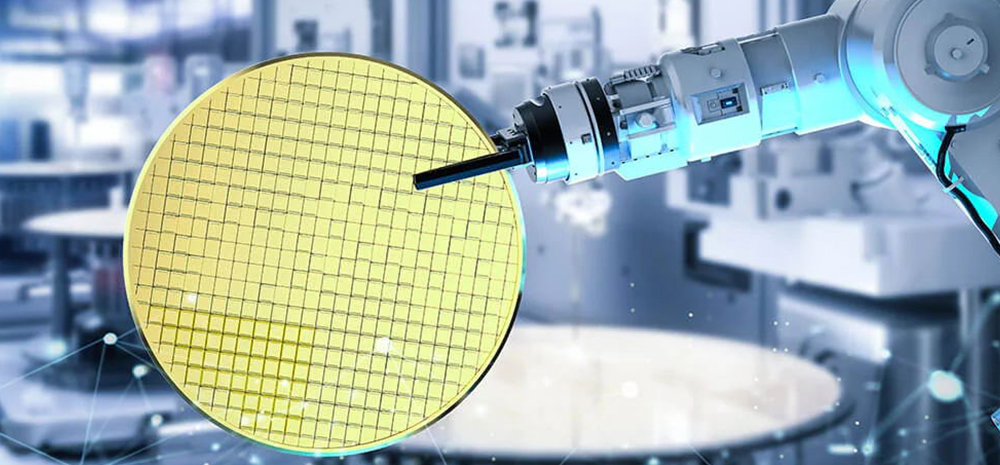

Generally, the semiconductor industry lies a critical yet often overlooked element: semiconductor equipment components. Semiconductor equipment precision components are the core of the entire semiconductor industry, with a broad market space and great development potential. The performance, quality, and precision of components directly determine the reliability and stability of semiconductor equipment, which enables better production of the tiny chips powering our digital world. This article delves into the essence of these components, exploring their significance, characteristics, and the various classifications that form the backbone of semiconductor manufacturing.

Understanding Semiconductor Equipment

To help deeply understand semiconductor equipment components, we must first understand the broader context of semiconductor equipment. Semiconductor equipment is mainly used in the manufacturing, packaging, and testing of integrated circuits. Usually, it can be subdivided into wafer processing equipment (front-end equipment) and assembly and packaging equipment (back-end equipment).

1. Wafer Processing Equipment

At the core of semiconductor production lies wafer processing equipment. These machines are responsible for transforming raw silicon wafers into functional chips through a series of intricate steps. Key wafer processing equipment include:

- Photolithography machines

- Etching machines

- Thin film deposition equipment

- Ion Implanter

- CMP equipment

- Cleaning equipment

- Inspection equipment

Photolithography Machine: The photolithography machine can transfer the designed circuit diagram from the mask to the photoresist on the wafer surface, and imprint the target pattern onto a specific material through exposure and development.

![]()

Etching Machine: It removes unnecessary parts of the chip through physical and chemical methods.

![]()

Cleaning Equipment: Cleaning equipment can clean the wafer surface without damage to remove impurities such as particles, metal contamination, polishing residues, etc.

Ion Implanter: This is a device that injects dopant materials into the surface of the wafer. The main purpose of this step is to form a PN junction, which is the basic structure of the working transistor.

![]()

Thin Film Deposition Equipment: Thin film deposition can add metal layers, insulating dielectrics, or other semiconductor structures to the wafer surface. The deposited thin film will serve as the functional material layer of the circuit.

CMP Equipment: CMP equipment achieves efficient removal of excess material on the wafer surface and global nanoscale flattening through the synergistic effect of chemical corrosion and mechanical grinding.

Inspection Equipment: Inspection equipment is used for quality control of front-end processes and advanced packaging.

2. Assembly and Packaging Equipment

Once the wafers have been processed, they must be assembled and packaged to create usable semiconductor devices. Assembly and packaging equipment mainly include:

- Die attach equipment

- Wire bonders

- Molding machines

- Trim and form equipment

- Test handlers

![]()

Die Attach Equipment: It is used to attach the die to the package substrate.

Wire Bonders: These machines create electrical connections between the die and the package.

Molding Equipment: These systems encapsulate the die and connections.

Trim and Form Equipment: Trim and form equipment is used to prepare leads on packaged devices.

Final Test Handlers: These machines handle packaged devices for final testing.

What are Semiconductor Equipment Components?

Semiconductor equipment components are the individual parts and subsystems that make up the larger semiconductor manufacturing equipment. These components meet the technical requirements of semiconductor equipment in terms of materials, structure, process, quality and precision, reliability, and stability. They are the foundation and core of semiconductor equipment and directly determine the reliability and stability of the equipment. Without high-quality components, even the most advanced semiconductor equipment would fail to produce the cutting-edge chips that power our modern world.

![]()

The Features of Semiconductor Equipment Components

Semiconductor equipment components form the bedrock of the modern digital age. They generally have the following characteristics:

1. Requirements for precision

Since semiconductor components are used in precision semiconductor manufacturing, their cutting-edge technology-intensive characteristics are particularly obvious compared to basic parts in other industries. They have the characteristics of high precision, small batches, multiple varieties, special sizes, complex processes, and extremely demanding requirements.

2. Need for Interdisciplinary Technical Talent

Semiconductor components are of many types, covering a wide range, and have a long industrial chain. Their R&D, design, manufacturing, and application involve cross-disciplinary and multidisciplinary integration of materials, machinery, physics, electronics, and precision instruments. Therefore, there is a great demand for interdisciplinary talents.

3. Materials Innovation

The materials used in semiconductor equipment components are at the forefront of materials science. These components often utilize:

- High-purity metals and alloys resistant to corrosion and contamination.

- Advanced ceramics with exceptional thermal and electrical properties.

- Specialized polymers designed for extreme environments.

- Exotic materials like synthetic diamond for unique applications.

4. Reliability and Durability

Components must be built to last. They often need to take into account composite functional requirements such as strength, strain, corrosion resistance, electronic properties, electromagnetic properties, and material purity during the production process.

5. Cleanliness and Contamination Control

In the world of semiconductor manufacturing, even a single particle of dust can ruin a chip. Therefore, semiconductor equipment components must be designed with cleanliness in mind.

Classification of Semiconductor Equipment Components by Service Object

According to the service object to points, semiconductor equipment components can be divided into precision machined components and commonly purchased components.

Precision Machined Components:

- Designed by engineers of each semiconductor equipment company and then outsourced processing, only for the use of the company’s equipment.

- Higher requirements on surface treatment, precision machining, etc.

- Typical components cover process chambers, transfer chambers, etc.

Commonly Purchased Components:

- Used by various equipment companies and also serve as spare parts and consumables in production lines.

- Highly versatile and standardized.

- Examples include silicon structural parts, o-rings, valves, gauges, pumps, gas shower heads, etc.

Classification of Semiconductor Equipment Components by Function

Based on the different functions of various types of components in the equipment, they can be divided into the following categories:

Mechanical: It plays the role of building the overall framework, basic structure, and wafer reaction environment, and realizing the special functions of parts in the equipment, ensuring the reaction yield and extending the service life of the equipment.

Electrical: The electrical type controls power, signals, and process reaction processes in the equipment. The core module is the RF power supply, which is directly related to the plasma concentration, uniformity, and stability in the cavity.

Mechatronics: It realizes wafer loading, transmission, motion control, and temperature control in the equipment.

Instrumentation: It needs to control and monitor flow, pressure, vacuum, temperature, and other values in the equipment. This requires extremely high response speed, measurement accuracy, and stability.

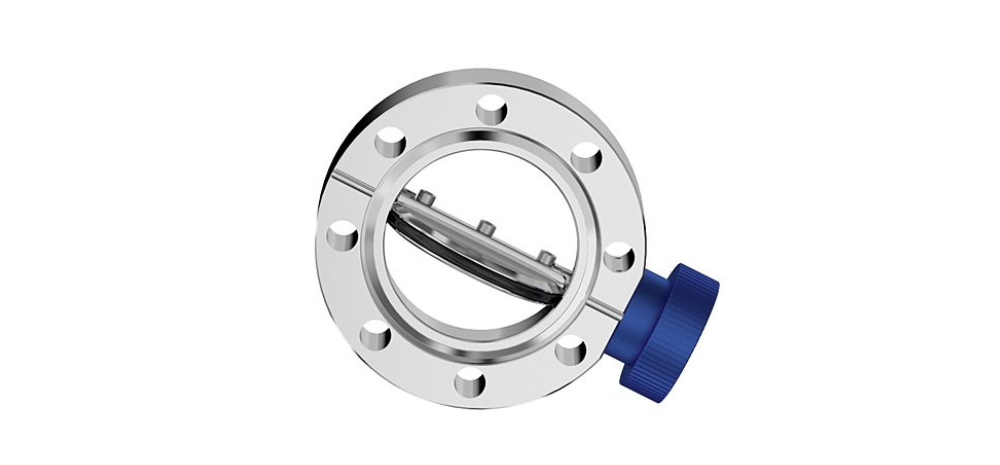

Gas/Liquid/Vacuum System: This category transmits and controls special gases, and liquids and maintains a vacuum in the equipment. It has high requirements for vacuum, corrosion resistance, and other properties.

Optics: It plays the role of controlling and transmitting light sources in optical equipment, and has extremely high requirements for optical performance. It is mainly used in lithography equipment and measurement equipment.

Classification of Semiconductor Equipment Components by Material

Semiconductor equipment components can be categorized into twelve main categories according to their main material and function of use, including:

- Silicon/Silicon Carbide components

- Quartz components

- Ceramic components

- Metal components

- Graphite components

- Plastic components

- Vacuum components

- Seal Components

- Filtration Components

- Motion Components

- Electrical Control component

- Other Components

Classification of Semiconductor Equipment Components by Internal Processes

According to the internal flow of the equipment cavity and the function realized to distinguish, semiconductor components subsystems and their typical products are below:

Fluid Management System: Gas flow controllers, liquid flow controllers, chemical delivery systems.

Integrated Process Diagnostic System: Gas analyzers, liquid analyzers, particle counters, and other metrology.

Optical System: Light sources, projection objectives, etc.

Power and Reactive Gas System: RF (Radio Frequency) power supplies, DC (Direct Current) power supplies, etc.

Thermal Management System: Coolers, heaters, temperature control devices, and temperature measurement systems.

Vacuum System: Dry pumps, molecular pumps, cryopumps, control valves, isolation valves, transfer valves, etc.

Wafer Processing System: Vacuum robotic arm, EFEM, etc.

Critical Components: Electrostatic chucks, seals, ceramic parts, etc.

FAR EAST TECH Offers High-Quality Semiconductor Equipment Components!

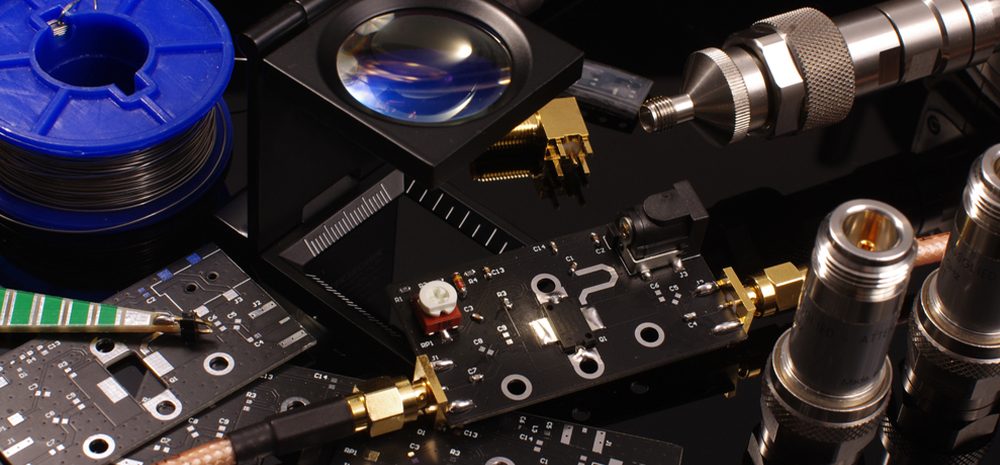

Looking for top-tier semiconductor equipment components? FAR EAST TECH is your go-to destination for high-quality products that meet the rigorous demands of the semiconductor industry. Our overseas product mall (Website: https://www.fareasttech.com/ ) offers a comprehensive range of semiconductor equipment components designed to enhance the performance and reliability of your equipment, mainly includes:

- Linear shafts

- clamping shaft collars

- Posts, post stands, strut clamps

- Locating pins & bushings

- Shaft supports

- Cantilever shafts, pivot pins, stepped screws

- Locating & positioning components

- Linear module

- Linear bearing & ball guides

- Manual positioning stages

- Ball screw support units

- Linear guides

- Self-lubricating bushing

- Lead screws & slide screws

- Linear actuators

- Screws & nuts

- Air source treatment Component

- Actuating elements

- Control elements

- Pneumatic elements

- Vacuum elements

- Shaft couplings

- Gears & racks

- Chains & sprockets

- Bearing & bearing accessories

![]()

Why Choose FAR EAST TECH?

1. Rich Expertise: FAR EAST TECH brings a wealth of experience, specializing in precision semiconductor equipment component research and production for a decade.

2. Professional Technical Team: Our dedicated technical team is at your service, offering efficient and personalized solutions that meet your unique requirements.

3. Customized Services: We specialize in customizing industry-specific new products, developed to your specifications.

4. Industry 4.0 Integration: We’ve adopted the latest in Industry 4.0 technologies to enhance our market position and offer cutting-edge solutions.

5. Global Partnerships: We pride ourselves on our extensive network, with partnerships spanning over 20 leading European firms, more than 60 North American businesses, and over 70 companies across the Asia-Pacific region.

Summary

Semiconductor equipment components are the unsung heroes of the technology world. Without them, the creation of the chips that power our devices would not be possible. As the industry continues to evolve, it is these components that will determine the pace and direction of technological progress.

Now visit the FAR EAST TECH Overseas Product Mall (Website: https://www.fareasttech.com/ ) to browse through our extensive collection of semiconductor equipment components. You’ll find everything you need to keep your semiconductor operations at the cutting edge.