The term “bearing” originates from the verb “bear,” which means to support or carry. In mechanical engineering, a bearing is a machine element that enables one part to bear or support another. It plays a pivotal role in the seamless operation of countless machines and devices we encounter daily. From the tiniest wristwatch to the most colossal industrial machinery, bearings silently toil away, ensuring smooth motion and reducing friction. But what exactly is a bearing, and why is it so important? Let’s get a closer look at this unnoticed but pivotal machine element.

What is Bearing?

At its core, a bearing is a machine element that limits relative motion to the intended motion and diminishes the friction between moving parts. For instance, a bearing might be designed to enable free linear movement of moving parts or to allow free rotation around a stationary axis. It could also restrict motion by managing the vectors of normal forces exerted on the moving parts. The primary function of most bearings is to reduce friction, thereby facilitating the desired motion.

Why is Bearing So Important?

The importance of bearings in the realm of mechanical engineering cannot be overstated. These unassuming machine elements serve as the linchpin for countless machines and devices, enabling them to function with efficiency and precision. Let us explore some of the key reasons why bearings are so crucial:

1. Friction Reduction

One of the primary functions of bearings is to minimize friction between moving parts. By reducing friction, bearings help conserve energy, prevent wear and tear, and extend the lifespan of machinery. This reduction in friction translates to improved efficiency, lower operating costs, and enhanced performance across a wide range of applications.

2. Load Support

Bearings are designed to support both radial and axial loads, distributing forces evenly and preventing excessive stress on individual parts. This load-bearing capability is essential in applications ranging from automotive engines to industrial turbines, where the ability to withstand high forces is paramount.

3. Precision and Accuracy

In many applications, such as robotics and precision manufacturing, the ability to maintain precise positioning and movement is critical. Bearings play a crucial role in achieving this level of accuracy by minimizing play and ensuring consistent, predictable motion.

4. Heat Reduction

By reducing friction, bearings also help minimize heat generation in mechanical systems. This is particularly important in high-speed applications, where excessive heat can lead to premature failure and reduced performance.

5. Noise Reduction

Well-designed and properly maintained bearings contribute significantly to noise reduction in mechanical systems. This is especially important in applications where quiet operation is desired, such as in consumer electronics or automotive interiors.

What are Common Types of Bearings?

Bearings come in a variety of types, each suited to specific applications. Let’s explore some of the most common types:

Plain Bearing

Plain bearings are among the simplest and most widely used types of bearings. They consist of a shaft rotating in a hole, with the surfaces separated by a thin film of lubricant. Plain bearings are valued for their simplicity, low cost, and compact design. They are commonly used in low-speed applications and can be found in everything from door hinges to automotive suspension systems.

Rolling-element Bearings

Rolling-element bearings are perhaps the most recognizable type of bearing, characterized by the use of balls or rollers to reduce friction between moving parts. There are two main subtypes of rolling-element bearings:

a) Ball Bearings: These bearings use spherical balls to maintain separation between the bearing races. Ball bearings are versatile and can handle both radial and axial loads. They are commonly used in applications requiring high speeds and precision, such as electric motors, bicycles, and skateboard wheels.

b) Roller Bearings: Instead of balls, roller bearings use cylindrical, linearly-tapered, or spherical rollers. These bearings are designed to handle heavier loads than ball bearings and are often used in applications such as automotive transmissions, conveyor systems, and heavy machinery.

Jewel Bearing

Jewel bearings are a specialized type of plain bearing that uses jewels, typically synthetic sapphire or ruby, as the bearing surface. These bearings are prized for their extremely low friction and wear resistance, making them ideal for use in precision instruments such as watches, compasses, and scientific instruments.

Fluid Bearing

Fluid bearings utilize a thin film of fluid, either liquid or gas, to separate the bearing surfaces. This fluid film can be generated externally (hydrostatic bearings) or by the relative motion of the surfaces themselves (hydrodynamic bearings). Fluid bearings offer exceptionally low friction and can support very high loads, making them suitable for applications such as large turbines, high-speed spindles, and precision instruments.

Magnetic Bearing

Magnetic bearings represent the cutting edge of bearing technology, using magnetic levitation to suspend a rotating shaft without physical contact. These bearings offer virtually zero friction and wear, as well as the ability to operate in extreme environments. However, their complexity and cost limit their use to specialized applications such as flywheel energy storage systems, and some types of compressors.

Flexure Bearing

A flexure bearing is a type of flexure designed to allow compliance in one or more angular directions. Flexure bearings perform roles similar to traditional bearings or hinges in scenarios where angular compliance is needed. A key advantage of flexure bearings is that they operate without the need for lubrication and generate little to no friction during use.

Main Factors Affecting Bearing Performance

Several factors can influence the performance and lifespan of a bearing:

Load: The weight and forces exerted on the bearing.

Speed: The rotational speed of the bearing can affect heat generation.

Friction: The resistance to motion between the bearing surfaces.

Lubrication: Proper lubrication is essential to reduce friction and wear.

Material: The type of material used in the bearing affects its durability and performance.

Temperature: Operating temperature affects the viscosity of lubricants, the dimensional stability of bearing components, and the overall performance of the bearing.

Alignment: Misalignment between shaft and bearing can lead to increased friction, premature wear, and reduced performance.

Contamination: The presence of contaminants such as dust, moisture, or debris can severely impact bearing performance and lifespan.

Applications and Uses of Bearing

Bearings are ubiquitous in the world of machinery. Here are some of their applications:

Automotive Industry

Bearings are found throughout modern vehicles, from wheel bearings and transmission components to engine internals and steering systems. They play a crucial role in ensuring the smooth, efficient, and reliable operation of automotive systems.

Aerospace Industry

The aerospace industry relies heavily on high-performance bearings for applications such as jet engine turbines, control surfaces, and landing gear. These bearings must operate reliably under extreme conditions of temperature, speed, and load.

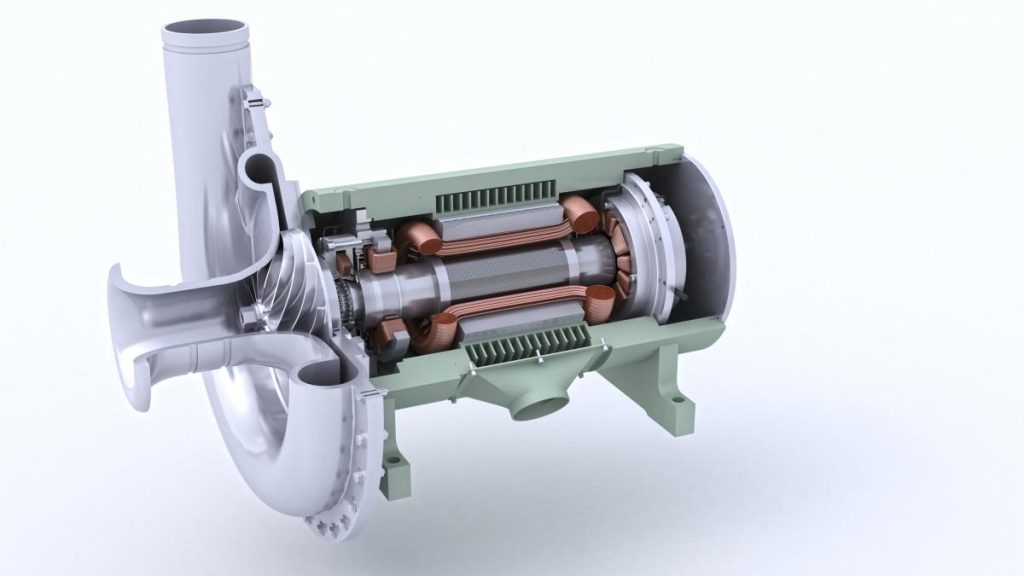

Industrial Machinery

Bearings are essential components in a wide range of industrial equipment, including pumps, compressors, conveyor systems, and manufacturing machinery. They enable the smooth and efficient operation of these systems, contributing to increased productivity and reduced downtime.

Energy Generation

Power generation systems, such as wind turbines, hydroelectric generators, and steam turbines, all rely on bearings to support massive rotating components and ensure efficient energy conversion.

Medical Devices

Precision bearings are used in various medical devices, including dental drills, MRI machines, and surgical robots, where accuracy and reliability are paramount.

Summary

Bearings are not just machine elements; they are the backbone of modern technology. From the smallest watch to the largest wind turbine, bearings enable motion and precision. As technology continues to evolve, so too will the capabilities and applications of bearings, ensuring they remain a vital component of our technological landscape. For more information about bearings, please visit FAR EAST TECH Overseas Product Mall (Website: https://www.fareasttech.com/).